FORMLABS

I joined Formlabs in 2013, right as their Kickstarter was coming to a successful close with ~$2M raised. As one of the first marketing hires, I played a key role in shaping the company’s creative strategy and managed content production through their transformation from a 20 person startup to a $2B+ business with 650+ employees around the world.

I also built the Formlabs Customer Success Team from scratch before handing off those responsibilities to a dedicated lead.

Section Guide

1. Form 3 and 3L Launch

2. Ceramic Resin and Color Kit Launch

3. COVID

4. Times Square Insallation

Form 3 and 3L Launch

Primary Role: Creative Producer, Content Capture, Launch Strategy

As the sole producer for the highly anticipated launch of the Form 3 and Form 3L at Formlabs, I played a pivotal role in orchestrating every aspect of the production materials for launch. From storyboarding and location scouting to talent recruitment, vetting 3D graphics studios, sourcing a composer for music, and overseeing the final post-production process, I ensured a seamless progression at each stage of the content creation journey.

On Time And On Budget

The Form 3 mechanics were a major departure from the Form 2. Instead of a galvanometer-based system, the Form 3 moved the entire laser housing back and forth to minimize distortion during printing. With this new print system and a larger printer never before tested in the market, we wanted to instill confidence in our customers by showing the benefits and flexibility of these new systems.

This shoot was complex, as it encompassed a range of locations spanning from poolsides to labs. As the sole producer behind this production, I managed all talent involved, orchestrating their seamless collaboration to ensure that the project remained on schedule and within budget.

Inside The Form 3

It was important to us that we showed how the new system within the Form 3 worked. Our budget made a quality 3D studio challenging to find, but after speaking with 6 different teams, Veli Studio in Helsinki Finland was willing to accept a printer as partial compensation for the work.

I worked with Veli Studio, our engineers, and our creative director to make sure the 3D assets created were both accurate and compelling to Formlabs customers. It took several rounds of story boarding before we moved into wireframe animations and final renders.

I also created the below wireframe animation to help explain to Veli Studio how the printers worked and what elements were needed in their production. This animation went on to be a valuable resource for the Formlabs MX teams as well.

Ceramic Resin and Color Kit Launch

Primary Role: Creative Producer, Content Capture, Launch Strategy

In order to stay competitive, Formlabs regularly released new resins to expand the capabilities of its printers. The design studio was tasked with trying something “out of the box“ and what we came up with was a series of assets featuring a new scientist character (who was actually our Customer Team Lead at the time).

With the release of our Ceramic Resin and Color Kit products, we created 2 videos that were meant to drum up interest. The content was very well received by the Formlabs customer base and led to further investment in experimental materials.

Limited Space, No Problem.

Being the solo producer on these projects, space and budget were limited. Much of the office was dedicated to R&D, so we had to get creative and film everything within a tiny conference room. It was also unclear if these products would be successful and so leadership did not want to invest a ton of money into the production of sleek launch videos.

With a skeleton crew, I drove the execution of the vision of our Creative Director with the resources we had on hand.

COVID | Swabs | Masks

Primary Role: Creative Producer, Partnership Coordination, Content Capture, Launch Strategy

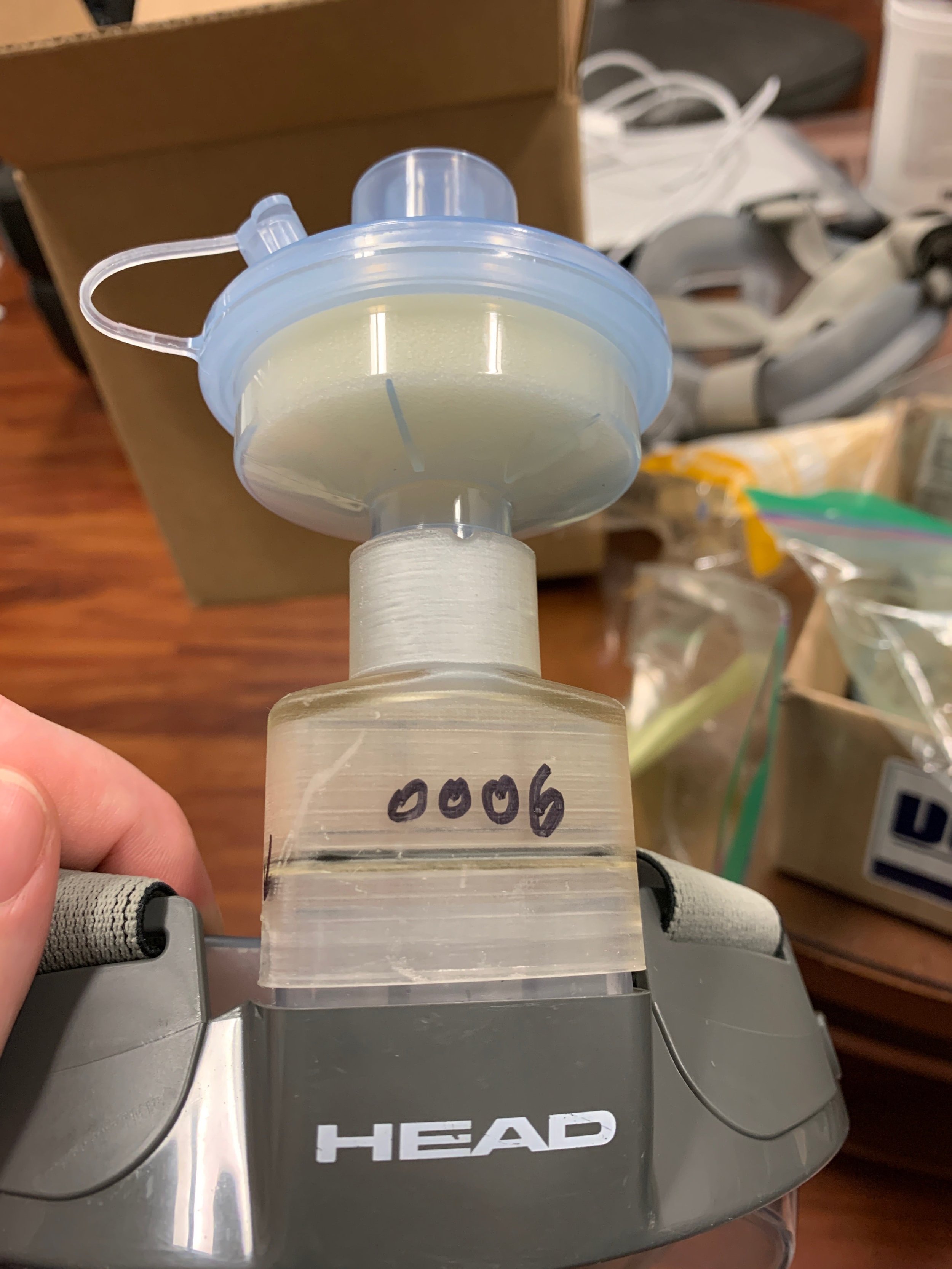

In a startup, you end up wearing many hats, but never did I expect to be leading efforts to mitigate an urgent respirator shortage at Mass General Hospital. When COVID hit, Formlabs was uniquely positioned to provide support. I helped manage a partnership with doctors at MGH to produce attachments for snorkel masks, adapting underwater equipment into makeshift but fully functional respirators at the height of the shortage.

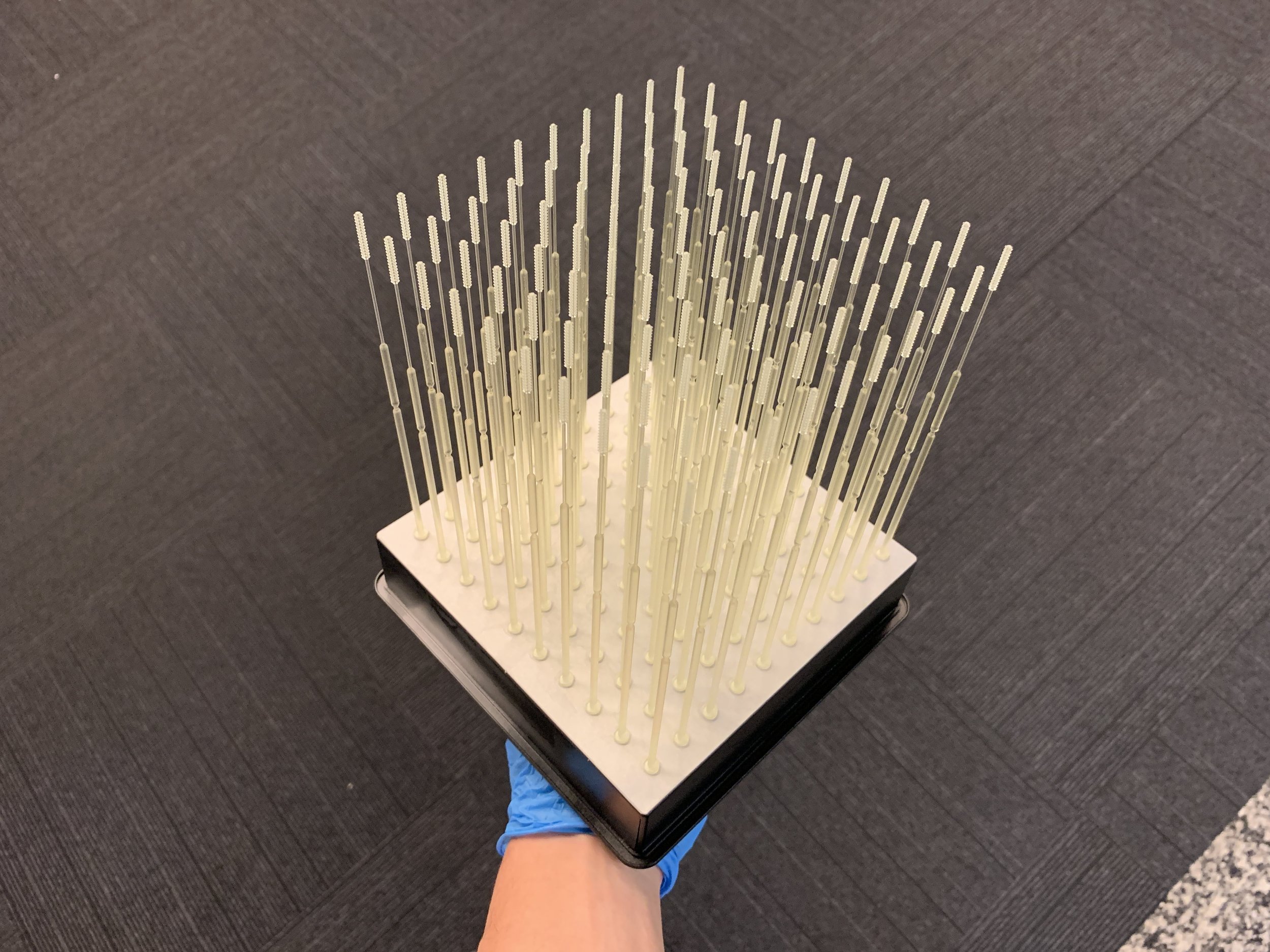

In tandem, Formlabs was working to bring a 3D printed nasal testing swab to market as fast as possible, made from their biocompatible resin. I brought on and managed Alex Pickering from Pickering Creative to document these events (and tested a few myself — a little discomfort for the greater good!).

How Do You Document A Pandemic?

It was very challenging to film anything as the virus was still new and no one understood the full extent of the risks. We took all the precautions we could and were able to document the collaboration between Formlabs, Onshape, and many local doctors to bring much-needed assistance to the Masks On project (producing respirators for ER workers) and nasal testing swabs to hospitals. Ultimately this footage was used for Formlabs’ public response to the pandemic, paid advertising, PR stories, and general news coverage of the tech sector’s efforts to help where it could.

Times Square Installation

Primary Role: Creative Producer, Launch Strategy and Logistics Coordinator

My work with Formlabs was not only limited to creative content production, but also management of large-scale initiatives like the production of the world's largest Fresnel lens. This art piece is a 10-by-12-foot Fresnel “lens” made of interlocking 3D printed bricks. I was the sole project manager overseeing all strategy and logistics for making this vision a reality.

I managed over 50 Formlabs 3D printers to create nearly 3000 individual pieces in addition to assisting with the documentation of the process that was eventually utilized for content on Youtube, social, and paid advertising.

Titled "Window to the Heart", we were the winner of the 2018 Times Square Valentine Heart Design Competition. Previous winners include The Office for Creative Research, Collective-LOK, Stereotank, Young Projects, and Situ Studio. You can read a little more about the project here: Times Square in a New Light: Designing a Large-Scale 3D Printed Lens.

A Massive Undertaking

When this project was brought to my team, we were not even sure it would be possible to execute within the time constraints. The margin for error was slim, but I sourced outside help to speed up production and even drove tiles myself to New York when we encountered printing issues so construction could begin with the supplies we had on hand.

In addition to construction challenges, we were also tasked with finding a way to move the 3000 pound completed structure, which involved sourcing and managing a giant crane company to move the lens from downtown NYC and install it in the middle of Times Square. Ultimately, the project was completed on time and had a successful feature and PR run.